Ink is one of the factors to produce beautiful printed products. Find out immediately the types of ink commonly used in printing and their applications in the following article.

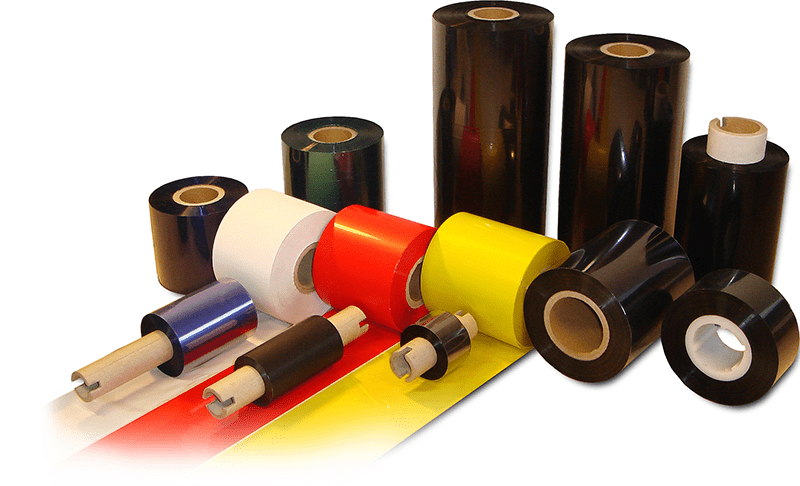

1. Ribbon ink – barcode ink

Ribbon ink is also known as barcode printing ink, thermal ribbon, barcode printing ribbon. This is a mechanical ink that has been used for a long time in the printing industry.

Ribbon ink is currently only used in special cases such as printing receipts or invoices. Other ribbons such as thermal ribbons can print higher quality and often print special pigments such as metallic foil, etc.

Currently, there are 3 main types of ribbon ink such as:

- Wax barcode printing ink: low cost, low melting temperature, less damage to the printhead, popularly used in industries that do not require high durability such as: items in supermarkets, transportation goods …

- Wax/ribbon barcode ink: is a commonly used barcode ink with good scratch resistance, heat resistance, often used to print high quality labels.

- Resin barcode ink: with high adhesion, it is applied to print barcode decal in high temperature, low humidity or frozen environment, … and is used in a number of fields such as: silver decal, decal pvc, apparel, frozen products.

Learn more about Ribbon Ink

2. Water-based printing ink – wood printing ink, carton paper

Water-based printing ink is used to print directly on materials made from cellulose such as cotton fabric, silk fabric, jute, hemp, rattan, sedge mat, wood, etc. It has the characteristic of being soluble in water at normal temperature. readily soluble from 50 to 60oC and hardly soluble below 25oC), can dry naturally without heat or light treatment. Its disadvantage is that it has less adhesion than oil ink because it has to use distilled water or solvent to dilute it when printing. However, it is very environmentally friendly. There are popular water-based inks such as: Matsui, Colorlab, Silkflex, Shinakamura, Furukawa, Csc, etc. Water-based inks are often pre-mixed colors used to print on materials such as wood, paper carton. As for fabric printing, use ink and core color sold separately.

However, the limitation of this type of ink is that it is often smudged, colorfast and fades over time. The fix for smearing is to use the right type of paper. As for fading, you need to consider inks that have a retention quality that is formulated with anti-fade pigments and uses a non-aqueous solution to make the ink resistant to water.

Please learn more about Water-Based Ink

3. Powder ink – laser ink

Powder ink used for laser printers, this ink is made by bonding a pigment with a polymer to form a fine powder with special electrical properties.

Principle of use: Inside the printer, there will be a laser and it will draw an image on the drum, which will be charged with an electrostatic charge and the drum will rotate on the toner cartridge, sucking the toner onto the paper and melt where it needs to be printed.

Powder ink has high durability and good quality, powder ink does not fade and is difficult to peel off, suitable for printing text and single line drawings, but not good for printing photos.

Please learn more about Powder Ink

4. Solid ink

Solid ink is a wax-like printing ink sold in small batches for each primary color used to create images on paper (cyan, magenta, yellow and black, or CMYK – cyan, magenta, yellow). , black). Inside the printer, the ink is melted and sprayed onto an oiled ink roller using the same technology used in offset printers.

The advantages of solid ink are fast printing speed, environmental friendliness, low toxicity and safe use at the allowable level, suitable for printing high-resolution color graphics and often used in office environments. room due to low maintenance costs. However, the cost of using this type of ink is quite higher than investing in a laser printer.

Please learn more at Solid ink

5. Oil-based ink

Oil-based ink, also known as oil-based ink, does not fade.

Oil-based ink produces prints with a long service life, does not smudge with water and does not fade without needing to be laminated or laminated. However, oil-based ink will produce a not-so-sharp print, the cost of replacing ink is high, and oil-based ink has UV glue, so it can cause clogging of the ink nozzle if not used properly. Oil-based printing ink is the type of ink commonly used to print decal labels.

Please learn more about Oil-Based Ink

6. Plastisol ink (light oil-based) – fabric printing ink

Plastisol ink is a specially formulated ink for printing on fabrics, has a light oil base, so it is a bit difficult to distinguish it, only when wiping the plate or using a solvent will it reveal the oil base. Its characteristics are that it can create a beautiful surface, better ink adhesion than water, more glossy than water, and can be blurred at will. Its disadvantage is that it has to be heat treated after printing.

Above are 7 types of ink commonly used in printing. Each type of ink will have different advantages and disadvantages as well as suitable for different types of printing materials and printing technologies.