Sublimation ink is one of the special inks, specialized for Sublimation thermal transfer printing technology.

1. Brief about Sublimation printing technology

Sublimation printing is a printing method to transfer images onto polyester fabrics.

Heat transfer is the process by which a substance changes from a solid to a gas without going through the liquefied state first.

During the heat transfer process, initially the solid ink particles are printed directly on the surface and then heated at high temperature and turned into a gas, with the high temperature also helping the polyester fabric to expand and allow Ink particles (in the gaseous state) sublimate into it to form colors for the fabric. Fabric after printing can be washed, ironed, dried without fading

2. What is Sublimation Ink?

Sublimation ink or Sublimation heat transfer printing ink is a kind of sublimation ink , which combines with solid dye and high temperature to print ink on printing material. The most used sublimation inks are Korean Inktec ink and Epson Sublimation ink.

This ink has the following properties:

- Sharp images, high color fastness.

- High transmission rate, easy to handle

- Good scratch resistance, wash resistance

- No damage to the nozzle

- The continuous ink system for thermal transfer printing includes 6 colors: Bk, M, Y, C, LM, LC to help bring prints with harmonious colors and easy to use.

- Compatible with all types of thermal transfer paper, produce products with outstanding vivid colors, image quality and high productivity.

- Sublimation inks work in high-speed printing without sacrificing color fidelity, withstanding temperatures up to 220ºC.

Note: Sublimation ink is a thermal transfer ink only, not a general thermal transfer ink. In addition to Sublimation inks, some water-based inks , oil-based inks , and offset inks are also considered thermal inks.

3. Working mechanism of ink in Sublimation printing technology

- Thermal transfer printing ink evaporates at high temperature and moves onto the surface of the paper.

- Next, they will open small holes in the surface of the paper for the dye to enter from the surface of the paper to the surface of the workpiece.

- When the dye has penetrated deep, the temperature is lowered, and the small holes in the surface of the paper are sealed. The dye also rapidly changes from a vapor to a solid state.

In short, the heat transfer printing process is the process of absorbing colors into the workpiece rather than coating the surface of the workpiece. Therefore, the colors are more durable and more realistic; usage time is longer.

4. Application of Sublimation ink

Sublimation ink has many colors; vivid, bright print colors; suitable for various nozzles and printers; It is suitable for many different printing materials, so it has many applications in different fields.

- Heat transfer printing on glass materials: Cups, vases, bowls, plates.

- Heat transfer printing on porcelain materials: Porcelain cups, porcelain cups, porcelain bowls.

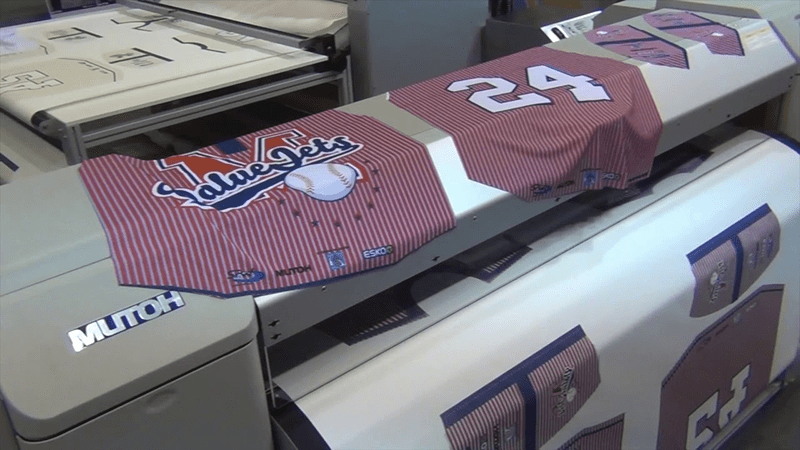

- Heat transfer printing on fabrics: Pillows, hats, clothes, shoes.

- Heat transfer printing on wood materials: Wooden items, wooden paintings.

- Heat transfer printing on plastic materials: Badges, keychains, phone cases.

- Heat transfer printing on ceramic tiles.

Thus, this can be considered as a versatile printing ink, which can be used to print on all types of products and materials. However, it is mainly used for shirt printing and cup printing.

5. Notes when using Sublimation ink

Thermal transfer printing technology is a popular printing technique, bringing high work efficiency. And to ensure that the printing is always as good, when using thermal transfer ink, it should only be used for printers. Because perhaps the printing facilities also understand, once the printer has been exposed to this particular ink, it is very difficult to change it with another ink.

Besides, thermal transfer ink when printing always comes with coatings. This coating absorbs the conductive ink to the surface of the product. So in the printing process they have to go hand in hand. It is also advisable to regularly check the ink and refill the ink in time to avoid falling into a shortage of ink while printing.

Please learn more: