UV printing is a printing technology for beautiful, sharp images, the ink layer adheres firmly to the surface of the printed material, and the ink layer can be felt slightly lumpy to the touch.

What is UV printing technology?

UV printing is a direct inkjet printing technology, as soon as the ink is printed on the printed material, the UV lamp shines UV rays to dry the ink quickly right after printing. Accordingly, the drying lamp will follow the ink jet unit, when the ink has just been sprayed on the surface of the printed material, the UV light will be directed down immediately to dry quickly. Using this technology, you can print multiple colors at once and print on a variety of media with different thicknesses. Specifically:

- Inkjet printers: Inkjet printers are mainly supplied in the Chinese, Japanese and European markets. The UV printers coming to the Chinese market often produce fast speeds, but in return, the products after printing are not as high-quality as the models from Europe.

- Ink nozzles: For ultra-fine ink particles, the machine can attach 6 or 8 nozzles depending on the print size as well as the printer used, the more modern the printer, the more nozzles are used, for print speed as well as different print products.

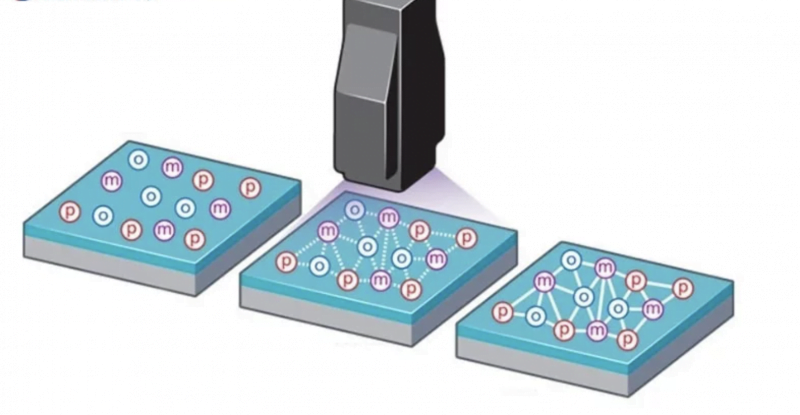

- UV ink: For UV printing technology, it is necessary to use a suitable ink, it must dry quickly under the action of UV rays. The UV printing ink is called Violet Ultra ink. It is still ink that prints on materials, but the ink dries through a completely different process. Instead of the solvents in the ink evaporating into the air and absorbing into the paper, UV inks dry (curing) through a photochemical process. When inks are exposed to ultraviolet (UV) light, they go from a liquid, or viscous, to solid. There is very little solvent evaporation and ink absorption into the materials. The advantage of UV printing inks is that there is very little emission of volatile organic compounds into the environment because there is no solvent evaporation like with conventional inks.

- UV drying lamp: This is a blue light UV lamp (UV LED or UV mercury lamp) mounted directly on the UV inkjet nozzle for the purpose of drying ink particles quickly, the UV lamp is mounted close to the nozzle. Near the printout, UV rays give enough intensity to dry the ink particles, not too high to affect human health, so UV printing is guaranteed to be friendly to the environment as well as to the user.

Initially, the idea of UV drying lamps did not originate from the printing industry but from the beauty industry. At that time, UV lamps are used to dry the nails quickly after painting, prevent color fading, and ruin the design. Realizing its use, they applied it to the field of printing.

In general, it can be understood briefly, UV printing technology consists of 2 basic stages:

- The printer nozzle injects ink onto the surface of the printed material

- UV drying lamp follows the nozzle, after the ink is sprayed, it will dry the ink immediately.

What is UV printing used for?

Depending on the needs and printing materials, UV printing is applied in many different areas of life:

- UV printing on glass: For making office glass walls, bathroom glass walls, glass signs, decorative cabinet glass walls … interior decoration of offices, houses, hotels, restaurants, shops…

- UV printing on Backlit Film: Used to make advertising light boxes, light-transparent light boxes.

- UV printing on fabric: Making pictures, printing T-shirts, briefcases, backpacks, fabric decals

- UV printing on paper: Printing paper labels (warranty stamps, broken decals, QC stamps, asset inventory stamps, error stamps, 7-color stamps), book covers, wedding cards, wall paintings…

- UV printing on canvas: Making advertising tarpaulins, banners, slogans…

- UV printing on Mica: Making signs, employee name plates, company boards, house number plates…

- UV printing on plastic: Printing plastic labels (transparent plastic, milk plastic …)

- UV printing on wood: souvenirs, wooden paintings, wooden boxes…

- UV printing on tiles: wall tiles, 3D painting tiles…

Advantages and disadvantages of UV printing technology

Advantages of UV printing

Print on many materials: UV printing technology uses UV ink, this is an oil-based ink that can adhere to many materials such as glass, wood, fabric, paper … to meet the needs of many different customers. . Also because of its high applicability, UV printing is used a lot in the field of advertising: making logos, braille signs, advertising light boxes…

Quick-drying ink: UV printing technology is equipped with a drying system with a UV lamp, so the drying speed is extremely fast, which can completely dry the ink color and ink coverage through just one drying at maximum speed. of the printer. This saves time, the print can be transferred to the processing stage or delivered to the customer without waiting. In particular, the print does not generate heat, does not absorb heat, ensuring the surface of the product is not changed and does not produce harmful odors.

For good print quality: UV drying lamp helps ink to adhere better, durable, long-lasting even in harsh weather conditions (hot and humid, high temperature), clear and bright print colors , does not smudge, it is also waterproof, scratch resistant. Moreover, you can print multiple color layers or multiple colors at the same time to create 3D effects for more vivid images, especially textures and patterns that always ensure sharpness. You can clearly see and feel the difference, printed images always have better depth and contrast. Durability on uv printed products can last from 5 to 15 years when hanging indoors, durability from 1 to 5 years for outdoor advertising applications.

Ink has a great thickness: Compared to other printing technologies, UV ink is much higher in quality. The ink is fresh, and when you touch it, you can clearly feel the thickness of the ink layer, which creates a high contrast for the print.

Safe for people in contact: UV ink is produced according to international standard processes, strict assurance, less toxic inorganic waste discharged into the environment. Therefore, workers working in UV printing factories are also safer and healthier. For users, publications printed with UV technology will also be safe and do not cause much harm.

Fast print speed: UV printing requires no surface preparation. Therefore, the printing time is shortened. Not only that, the fact that UV ink dries right in the printing process also contributes to speeding up the printing process.

Disadvantages of UV printing

In addition to the above advantages, UV printing also has some weaknesses such as:

- Ink will not dry on its own without the UV intelligent fusing lamp system, which is also a relatively large drawback of UV printing technology.

- Difficult to fix prints: UV ink has the property of sticking to the printed material, so if it gets dirty during the printing process, it is very difficult to clean and handle, the only way is to print from the beginning. Therefore, it requires the printing technician to be very careful and skillful.

- The price of UV printing is higher than normal printing: UV printers have a high investment cost, UV printing ink, equipment, nozzles, and detergents are also more expensive because they have to be imported from abroad. More expensive than other types of printing such as offset printing, flexo printing, etc.

What material and ink does UV printing use?

UV printing is one of the most applicable printing technologies on many materials today. Unlike Flexo printing, which is mainly on thin, flexible, rollable materials, or Offset printing that requires flexible printing materials and smooth surfaces, UV printing is used on a variety of materials with different thicknesses and states.

In addition to basic materials such as paper, plastic, fabric, silver, UV printing can also be applied on hard, thick and difficult to catch ink such as wood, glass, mica, stone, metal, … UV ink will stick firmly on the surface, slightly raised on the surface, durable, long-fading.

Regarding the ink used for UV printing technology, there are two types: oil-based UV ink and water-based UV ink. In general, oil-based UV inks are glossier than water-based UV inks, along with better visibility and durability.

Water-based UV ink is also dried by an infrared drying lamp system, the printing cost when using this ink is cheaper. For oil-based UV ink with high quality, good sun and water resistance, long color fastness, prints can be used for more than 5 years and printing costs are also higher.

You can find out more details at:

When should UV printing be used?

Although the cost of printing using UV technology is higher than that of Flexo or Offset printing , the speed of bulk printing is also slower. However, it is still chosen by many customers when they need to print quickly in small quantities and require good quality prints, beautiful colors, long-lasting colors, and long-lasting prints.

- Fast printing of small quantities: Because the ink is dried immediately after printing, and the printing speed of UV printers is fast, this technology will be suitable for customers who want to print quickly. However, UV printers have a smaller capacity, although the printing speed is fast, if printing in bulk will still be slower than Flexo and Offset. Therefore, it will be more suitable for small quantity printing.

- Beautiful print quality: UV ink is sprayed directly onto the surface of the printed material according to the printer’s automatic settings. Therefore, printed images appear vivid, true, bold colors and true to the template. In addition, because it is UV-cured right after printing, the ink dries quickly, adheres firmly to the surface, does not smudge, fade, and is durable over time.

What are the steps in the UV printing process?

The UV printing process is similar to the conventional inkjet printing process, except for the ink drying method. Conventional inkjet printing allows the ink to evaporate and dry over time, while UV printing uses UV rays to dry the ink quickly. After the ink is printed on the paper, a fusing lamp shines a UV light on the surface to dry the ink. The specific steps are as follows:

- Step 1: The design file is transferred from the computer to the printer.

- Step 2: The printer receives the image and transmits the signal to the nozzles.

- Step 3: The nozzles receive the signal and set the nozzle position in accordance with the design.

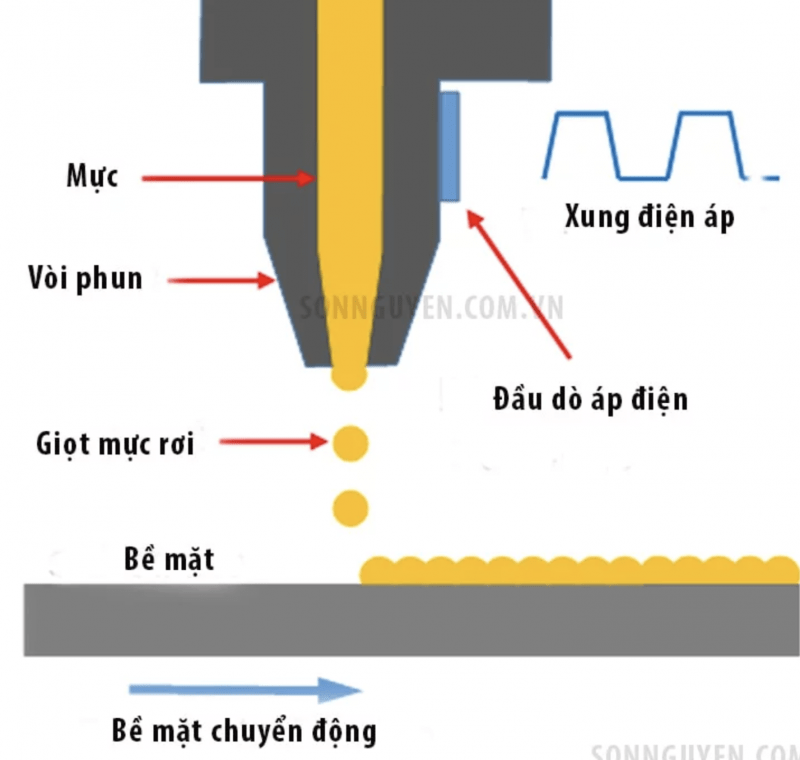

- Step 4: Ink is sprayed onto the surface of the printed material at the installed position thanks to the action of the electric pulse and voltage probe combined with the movement of the wire and the crane attached to the ink nozzle.

- Step 5: As soon as the ink is sprayed on the surface of the printed material, the UV lamp will shine UV rays to dry the ink quickly.

After printing is completed, the printing workshop can immediately deliver to the customer without having to wait for the ink to dry. If you want to protect the print surface better, you can request a printing surface lamination.