Solid ink is a wax-like substance sold in small batches for each primary color used to create images on paper. This ink is relatively safe for health and environmentally friendly.

What is solid ink?

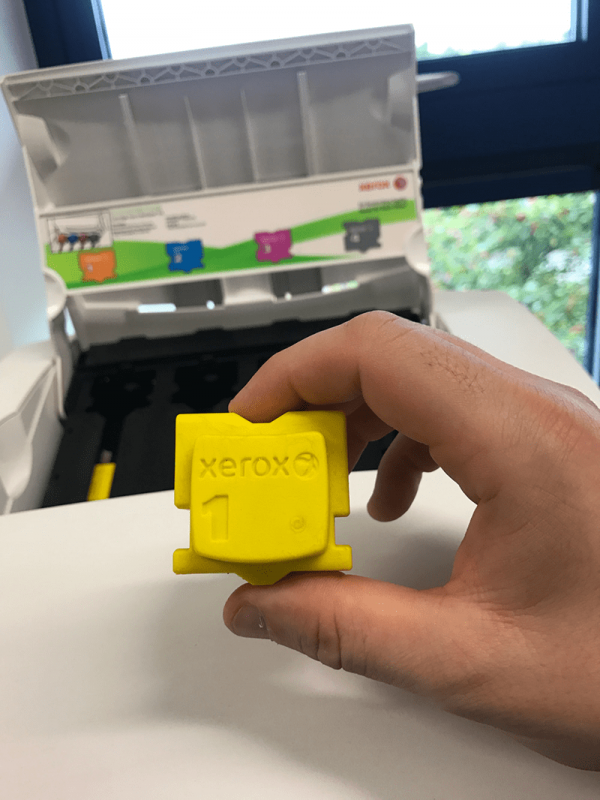

Solid ink is a wax-like printing ink, sold in small batches for each primary color used to create images on paper (cyan, magenta, yellow and black, or CMYK – cyan, magenta, yellow, black).

These inks are usually made with vegetable oils and wax-like materials. Inside the printer, the ink is melted and sprayed onto an oiled ink roller using the same technology used in offset printers. Therefore, the printing time is quite long, so it is not suitable to use decal label printing in large quantities. Instead, print decal labels Offset more suitable.

History of the development of solid ink

Solid ink was formerly developed by Tektronix, a company that was later acquired by Xerox, and today Xerox manufactures printers using this technology.

In the 1990s, a series of solid ink printers capable of printing up to Tabloid Extra size were introduced, including the Tektronix Phaser III, Tektronix Phaser 300, and culminating in the Tektronix Phaser 380 in 1997. An ink printer. large format , Phaser 600, introduced in 1996. The Phaser 600 is capable of using roll or feed paper up to 48 inches wide.

Some solid-ink printers use small spheres of solid ink, which are stored in a hopper before being transferred to the printhead. After the solid ink is loaded into the printing device, it is melted and used to create an image on the paper in a process similar to offset printing.

Xerox claims that solid ink printing produces more vibrant colors than other methods, is easier to use, can print on a wide range of media, and is more environmentally friendly due to reduced waste production. In the mid-1990s, the president of Tektronix actually ate a portion of a solid ink, to demonstrate that they were safe to handle.

Advantages and disadvantages of solid ink

The advantages of solid ink are fast printing speed, environmental friendliness (generating 90% less waste than laser printing), low toxicity and safe use at acceptable levels.

In addition, it also has other advantages as follows:

- Because it is made from natural bases, it does not affect the environment and does not cause harm to health. Therefore, solid ink does not need to be packaged in a typical plastic cartridge, saving a small amount of money.

- The printing process uses solid inks similar to offset printing, so the image always comes to life on almost any paper, including recycled paper.

- Prints with solid ink for uniform ink color, no color spill, dark and light spots.

- Solid ink has a wider range of colors than liquid ink for laser or inkjet printers.

- Solid ink is suitable for both paper or other printing media with uneven surfaces.

- Solid ink for vibrant, vivid print colors is suitable for printing high-resolution color graphics and is more commonly used in office environments due to low maintenance costs.

However, the cost of using solid ink is higher than that of other inks and is also difficult to find in the market. At the same time, there should be a dedicated printer dedicated to it. Therefore, this ink is only used in professional graphic design studios.

Thus, solid ink is a type of ink that gives beautiful and safe print quality, but has a high cost. Therefore, businesses should consider using this ink for professional graphic design cases.

Plus, you can learn more about other inks: