Sublimation ink technology is a concept often confused with thermal transfer printing. In fact, these two concepts have differences that businesses need to pay attention to so as not to be mistaken when choosing the right printing technology for their products.

1. What is ink sublimation technology?

Ink sublimation technology is a technology that uses ink sublimation, when the ink is heated to a certain temperature, it will change from a solid to a vapor form without having to undergo a liquefaction stage. .

Thus, we see that: this technology sounds strange, but actually it has been applied a lot in human life. Basically, sublimation printing technology works when the thermal paper (Sublimation paper) has the image printed with sublimation ink, is placed on the material and of course under the right temperature conditions will help the printed image appear more vivid. onto the surface of the material you need to print.

Sublimation ink is a step that uses sublimation ink in printing technology, namely, it will change from a solid to a vapor when heated to a certain temperature without going through the process. liquefied. In technical terms, this is a heat transfer printing technique .

Normally, purchase invoices often use thermal paper, and price lists – such as envelopes or any kind of quotation sheet, rarely use thermal paper as well as technology . this sublimation ink.

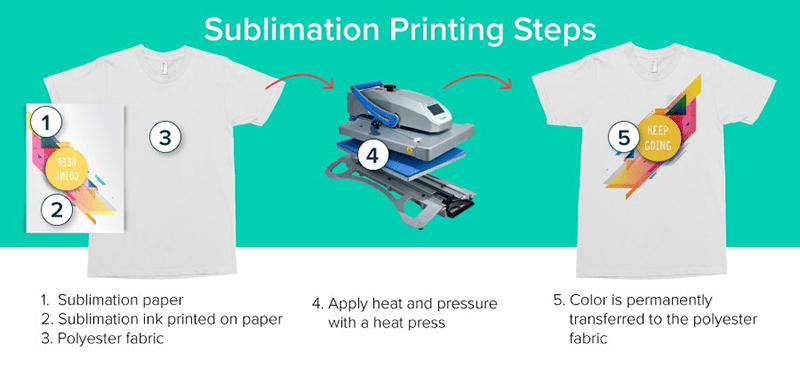

2. Sublimation printing process

Step 1: Design the print

Printed images can be ordinary images, vector images, text, effects, designed by a specialized software on the computer such as Corel, AI, Photoshop.

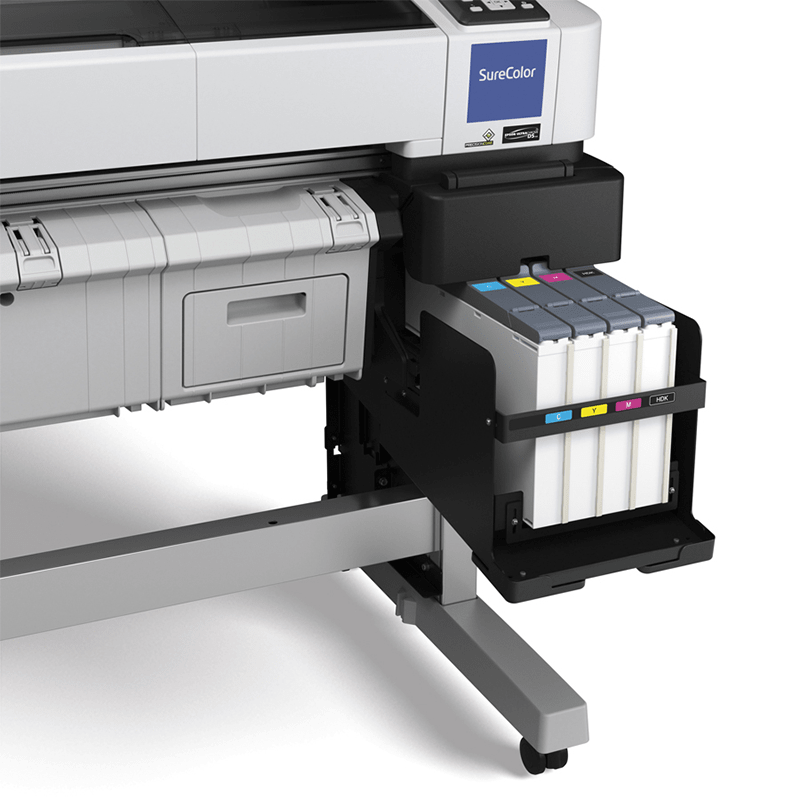

Step 2: Print the image with a color printer with sublimation ink

The printed image will be printed by a color printer filled with sublimation ink on specialized thermal transfer paper.

Step 3: Fix the print on the printed material with heat-resistant tape

In order for the heat transfer ink to adhere to the print material, make sure the media is coated with a chemical that captures the heat transfer ink. The print will then be cut off the excess and fixed on the printing material with heat-resistant tape.

Step 4: Put the printed material into the press and press

Presses are available in various types depending on whether the shape of the printed material is flat or curved, pressing time and pressing temperature depending to ensure the maximum transfer of print quality.

Step 5: Remove the product from the press, remove the transfer paper.

The product after being pressed and removed the transfer paper should be carefully checked to ensure the quality of the finished product.

3. Comparison of ink sublimation and heat transfer printing technology

The process technology is the same as thermal transfer, so people confuse it with thermal transfer printing. It is also printing to paper, pressing with a dedicated printer, but in fact these two technologies have differences that many people confuse. Businesses need to note the differences below to choose the right printing technology.

Compare two technologies when printing on fabric

For ease of comparison, below is the printing process of these two technologies on fabric.

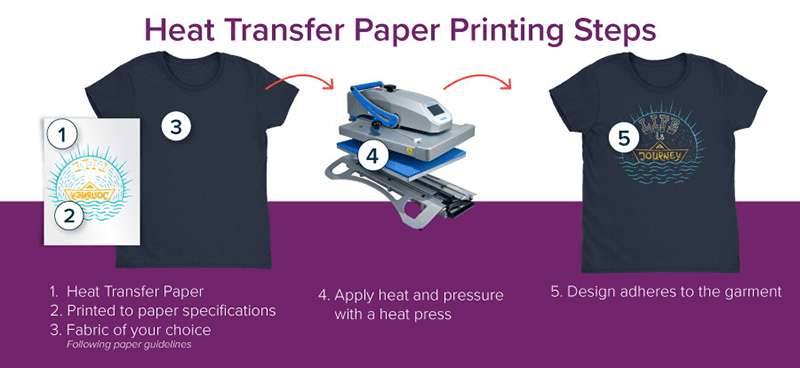

Heat Transfer Printing is a technology favored by many printing factories in Vietnam. This technology uses a type of thermal transfer paper (Heat transfer paper) printed by inkjet or laser printers. Then bring the paper to place on the shirt, press the fabric to the fabric surface or use a household iron. Then peel off the paper, the whole design will stick to the fabric surface. It is also because this printing technology is quite easy, fast and cost-effective, so it is very suitable for small printing shops or family workshops.

Dye Sublimation Printing is different in that it uses a specialized ink and paper ( Sublimation ink , Sublimation paper). Sublimation ink, when heated by heat, will change from a solid to a liquid, print on Sublimation paper and then press the paper onto the fabric surface. The ink will adhere to the polyester fabric. When the ink cools, it turns back to a solid state and will stick to the fabric permanently. The ink layer when finished printing almost “eats” into the fabric, feeling it is part of the fabric. In addition, this technology allows printing on cups, mugs, paintings, canvas, bags, etc. as long as poly coating is applied.

Conclude

Thus, heat transfer printing technology can print on cotton and polyester fabrics, while sublimation printing can only print light-colored polyester fabrics.

Sublimation printing technology allows you to print in full color with full tint. As for thermal transfer printing, the results depend a lot on the quality of the thermal transfer paper and the results are not as satisfying as sublimation.

Sublimation printing technology for greater durability when the sublimated ink almost adheres to each fabric, each element of the printed object. The heat transfer printing layer will feel less durable than sublimation, easily fade, create a feeling of cracking over time and many washings (for fabrics). In addition, there are many types of thermal transfer paper, and basically the paper is cheap and expensive for different quality.

Sublimation printing can print on many surfaces (hard, soft fabrics, cups, bags). And heat transfer is basically impossible.

In terms of cost, sublimation printing technology will be a little more expensive than heat transfer printing and requires more investment in terms of equipment, materials, etc.

Thus, it is clear that these two technologies are completely different in terms of investment materials, costs, processes as well as results. Understanding these differences will help businesses choose the right printing technology suitable for their products to require the printing factory to produce.

Please learn more: